Efforts in Quality Control Department

Yao kanaami's products are manufactured to meet the strictest standards to achieve ever higher product quality.

Experienced inspectors conduct 100% inspection, maintain an inspection database for all products, and feed back the results to the staff responsible for product quality at meetings.

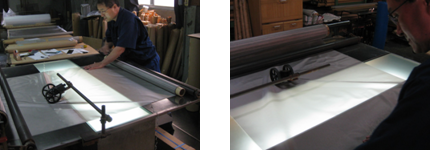

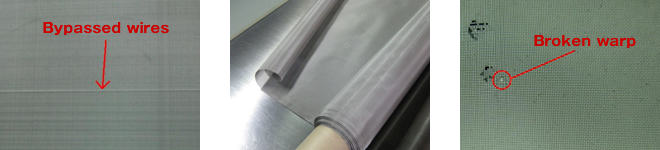

Wire mesh is inspected while winding it around a paper cylinder on an inspection table. Inspectors have to detect defects visually and by touch as shown in the table below. This requires skills and experience, particularly when inspecting fine mesh formed from wires thinner than 0.1mm.

Experienced inspectors conduct 100% inspection, maintain an inspection database for all products, and feed back the results to the staff responsible for quality at meetings where any problems detected are tackled to solve.

| Inspection items | Inspection methods |

|---|---|

| Broken warp: defect caused by broken warp in wire mesh | Visual and touch inspection, with loupe |

| Curling: Wire mesh has curled in the longitudinal direction. | Visual inspection |

| Kink: Curled weft is inserted. | Visual and touch inspection, with loupe |

| Aperture shape: Test sieve is required to have open area with clear angles. | Universal projector |

| Aperture size: Must be within the range of standard criteria. | Universal projector |

| Mesh number in warp direction and in weft direction is checked. | Fiber standard scale, Mesh counter |

| Poor spacing: Variability of aperture size in warp direction. | Visual inspection |

| Stain | Visual inspection |

| Mesh thickness: Wire mesh for screen printing must be checked for the thickness. | Digital thickness gage (Digimatic) |

| Tensile test: Some wire mesh for screen printing is required to pass this test. | Tensile tester |

| Inclusion of foreign matter | Microscope |

| Length, wire width | Length gage, straight rule |

Inspection data is stored in database and is fed back every day to the staff responsible for product quality.

The products are inspected by skilled inspectors both visually and by touch.

Left: Bypassed wire![]() /Middle: Curled mesh

/Middle: Curled mesh![]() /Right: Broken warp

/Right: Broken warp![]()

Left: Inspection of mesh (Fiber standard scale used), Middle: Inspection of thickness, Right: Inspection of aperture shape and size (Universal projector)

We measure the filtration data of various wire mesh elements and maintain a record of the data. This data is used by the Sales Department to support customers as well as for in-house quality control and improvement.