Efforts in Production Department

Efforts in Weaving Section

- 1. To carry on our technology and to continue to improve it is our mission.

- Kawachi cotton originated and developed in the district including Yao city, Matsubara city and Higashi-Osaka city. We have developed this district’s traditional cotton weaving technology into the technology of weaving extremely fine wires into mesh, and will continue to further develop the technology and carry it further.

Left: Kawachi cotton weaving

Middle: Handloom weaving of wire mesh

Instructing a young worker

- 2.We have been developing our trusted relationships with our customers and suppliers.

- Quality of wire mesh, particularly of the ultra-fine wire mesh for which we are renowned, depends heavily on the quality of the machines including the weaving machines and reeds and their components and attachments as well as on the material quality. Manufacture of ultra-fine wire mesh of high quality is supported by our trusted relationships with our customers and suppliers. Production of ultra-fine wire mesh requires the expertise of matching various components with each other and fine-adjusting their relationships for the best coordination, for which the Japanese are held in high esteem.

- 3.We only use rigorously selected materials.

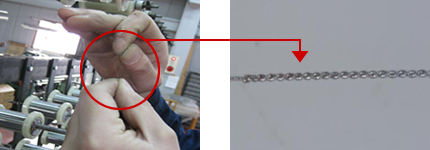

- Ultra-fine wire mesh of high quality can only be manufactured from high-quality materials. Ultra-fine wires measuring 0.05mm to 0.015mm in diameter cannot be made of mediocre materials. We use materials purchased from rigorously selected suppliers.

Splicing: An ultra-fine wire, when broken, is recovered by joining the ends together while twisting, a task that only a skilled artisan can perform.

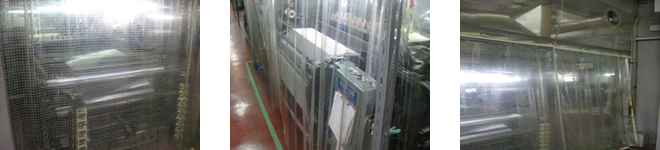

- 4.Meticulous practice maintains the shop floor always clean.

- Dust can cause wire breakage. We always maintain a clean working environment.

Weaving machines are individually protected from dust. Production is carried out in a clean, air-conditioned room.

Entrance to the weaving room

- 5.We never slacken the pace of advancing the technology and meeting challenges of manufacturing.

Efforts at Aichi Filter Plant

- The filter manufacturing division's top priority is to make clean products.

- The products are subject to the most rigorous inspection.

- We never stop challenging in the art of production.

Press room, washing room and inspection room are separated to protect the products from dust.

The products are cleaned in an ultrasonic washer before being dried in a furnace.

Strict inspection methods are implemented.

Packaging of filters

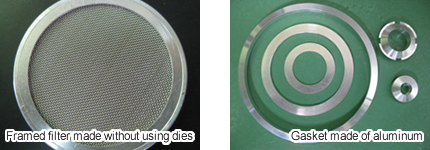

We are ready to take orders for prototypes or metal gaskets of small lots, which do not include the cost of dies.