Sieve, classifier (screen)

Test sieve

We have long and extensive experience in manufacturing wire mesh used to make test sieves for such applications as grading control and removal of foreign matter. Our successful record ensures high quality wire mesh with precise mesh size and uniform open area size.

We have long and extensive experience in manufacturing wire mesh used to make test sieves for such applications as grading control and removal of foreign matter. Our successful record ensures high quality wire mesh with precise mesh size and uniform open area size.

Test sieve specifications

| Open area (mm) | mesh | Wire diameter (mm) |

|---|---|---|

| 2.80 | 7 | 1.10 |

| 2.36 | 8 | 1.03 |

| 2.00 | 9 | 0.93 |

| 1.70 | 10 | 0.83 |

| 1.40 | 12 | 0.73 |

| 1.18 | 14 | 0.63 |

| 1.00 | 16 | 0.56 |

| Open area(µm) | mesh | Wire diameter(mm) |

|---|---|---|

| 850 | 18.8 | 0.50 |

| 710 | 22.0 | 0.45 |

| 600 | 25.4 | 0.40 |

| 500 | 31 | 0.32 |

| 355 | 44 | 0.224 |

| 300 | 51 | 0.20 |

| 250 | 62 | 0.16 |

| 212 | 72 | 0.14 |

| 150 | 102 | 0.10 |

| 125 | 120 | 0.090 |

| 106 | 144 | 0.071 |

| 100 | 150 | 0.070 |

| 90 | 166 | 0.063 |

| 75 | 200 | 0.052 |

| 63 | 235 | 0.045 |

| 53 | 285 | 0.036 |

| 45 | 330 | 0.032 |

| 38 | 375 | 0.030 |

| 32 | 450 | 0.025 |

| 25 | 500 | 0.025 |

| 20 | 635 | 0.020 |

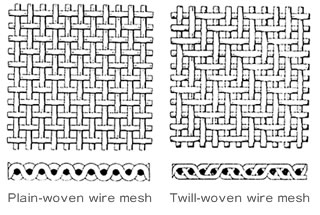

Plain/twill-woven wire mesh

Plain/twill-woven wire mesh (square mesh) has been widely used to form filters and sieves. Weaving method is selected to meet such factors as the open area-to-wire size ratio and the application.

Plain/twill-woven wire mesh (square mesh) has been widely used to form filters and sieves. Weaving method is selected to meet such factors as the open area-to-wire size ratio and the application.

We have acquired high reputation particularly for our expertise in manufacturing fine mesh with aperture of 150µand smaller.

Plain/twill-woven wire mesh specifications: Detailed specifications can be found here.

- Mesh size

- 2 to 5 (Aperture size about 4.13mm to 11.2mm)

6 to 10 (Aperture size about 1.44mm to 3.58mm)

12 to 16 (Aperture size about 0.94mm to 1.74mm)

18 to 30 (Aperture size about 0.5mm to 1.21mm)

32 to 150 (Aperture size about 0.099mm to 0.57mm)

165 to T635 (Aperture size about 0.025mm to 0.109mm)

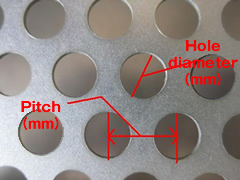

Punching metal

Steel sheet punched out with a press die to form a multitude of holes; it is also called punchout metal mesh.

Steel sheet punched out with a press die to form a multitude of holes; it is also called punchout metal mesh.

Standard specifications are: hole diameter 0.35 to 50mm; pitch 1 to 45mm; percentage of open area 10 to 60%. The hole shape may be round, cross, square, oval, etc. The holes are arranged in 60°staggered or parallel arrays.

Punching metal is used as a cover that passes air or sound, in sound insulation/heat insulation panel, interior/exterior material of buildings, strainers, granulation/crushing machine, sifting of grains, gravel or pharmaceutical materials, etc.

Punching metal cannot be used in filtration of fine particles due to limitations on the size of holes that can be formed, but it is used to reinforce the main filter.

Specifications of punching metal (SUS304)

| Sheet thickness | D×P (60°staggered) | Percentage of open area |

|---|---|---|

| 0.5t | 2×3 | 40.30% |

| 3×5 | 32.60% | |

| 5×8 | 35.40% | |

| 0.8t | 2×3 | 40.30% |

| 3×4 | 51% | |

| 3×5 | 32.60% | |

| 4×7 | 29.60% | |

| 5×8 | 35.40% | |

| 6×9 | 40.30% | |

| 8×10 | 58% | |

| 1t | 2×3 | 40.30% |

| 3×4 | 51% | |

| 3×5 | 32.60% | |

| 4×7 | 29.60% | |

| 5×8 | 35.40% | |

| 6×9 | 40.30% | |

| 8×10 | 58% | |

| 8×12 | 40.30% | |

| 10×12.5 | 58% | |

| 10×15 | 40.30% | |

| 1.5t | 3×4 | 51% |

| 3×5 | 32.60% | |

| 4×7 | 29.60% | |

| 5×8 | 35.40% | |

| 6×9 | 40.30% | |

| 8×10 | 58% | |

| 8×12 | 40.30% | |

| 10×12.5 | 58% | |

| 10×15 | 40.30% | |

| 2t | 3×5 | 32.60% |

| 4×7 | 29.60% | |

| 5×8 | 35.40% | |

| 6×9 | 40.30% | |

| 8×10 | 58% | |

| 8×12 | 40.30% | |

| 10×12.5 | 58% | |

| 10×15 | 40.30% |

Mesh conveyor

Wires used to form mesh conveyors must be resistant to the atmosphere and chemicals to which the conveyor would be exposed, and the heat applied during heat treatment in such processes should also be taken into account. Thickness of wire and aperture size are determined in accordance with the weight carried by the belt and the load-bearing capability of the belt.

Six basic types of conveyor belts

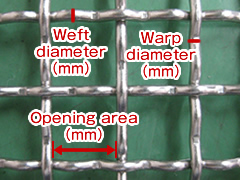

Crimped wire mesh

Weft wires are inserted between undulated warp wires so as to prevent the wires from moving. Wire diameter is usually from 1.5 to 5Φ, open area is from 6 to 90mm. The wire mesh is used for sifting, drying, and other applications.

Weft wires are inserted between undulated warp wires so as to prevent the wires from moving. Wire diameter is usually from 1.5 to 5Φ, open area is from 6 to 90mm. The wire mesh is used for sifting, drying, and other applications.

Specifications of stainless steel crimped wire mesh

| Wire diameter(mm) | 5 | 4 | 3 | 2.5 | 2 | 1.5 |

|---|---|---|---|---|---|---|

| Open area(mm) | 10 | 15 | 12 | 10 | 7 | 6 |

| 20 | 18 | 15 | 11 | 8 | 7 | |

| 25 | 20 | 18 | 12 | 9 | 8 | |

| 32 | 22 | 20 | 15 | 10 | 9 | |

| 35 | 25 | 21 | 18 | 11 | 10 | |

| 40 | 32 | 25 | 20 | 12 | 11 | |

| 50 | 35 | 27 | 25 | 15 | 12 | |

| 60 | 40 | 30 | 30 | 18 | 15 | |

| 70 | 45 | 31 | 31 | 20 | 18 | |

| 80 | 50 | 35 | 35 | 23 | 20 | |

| 90 | 60 | 37 | 40 | 25 | 23 | |

| 70 | 40 | 45 | 32 | 25 | ||

| 45 | 50 | 35 | ||||

| 50 |

Specifications of Zinc-plated crimped wire mesh

| Wire diameter(mm) | 5 | 4 | 3 | 2.5 | 2 | 1.5 |

|---|---|---|---|---|---|---|

| Open area(mm) | 20 | 15 | 12 | 10 | 7.5 | 6 |

| 25 | 18 | 15 | 11 | 8.2 | 7 | |

| 31 | 20 | 18 | 12 | 9 | 8 | |

| 35 | 22 | 20 | 15 | 10 | 9 | |

| 40 | 25 | 21 | 18 | 11 | 10 | |

| 50 | 31 | 25 | 20 | 12 | 11 | |

| 60 | 35 | 27 | 21 | 15 | 12 | |

| 70 | 40 | 30 | 24 | 18 | 15 | |

| 45 | 31 | 25 | 20 | 18 | ||

| 50 | 35 | 30 | 21 | 20 | ||

| 60 | 37 | 31 | 25 | 25 | ||

| 70 | 40 | 35 | 31 | |||

| 45 | 40 | 35 | ||||

| 50 | 45 | 40 | ||||

| 60 | 50 |

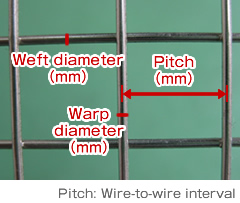

Welded wire mesh

Wire mesh formed by spot welding the warps and wefts together at their intersects. There are wide applications such as reinforcement of concrete beds, ceiling louvers and other display products.

Wire mesh formed by spot welding the warps and wefts together at their intersects. There are wide applications such as reinforcement of concrete beds, ceiling louvers and other display products.

Specifications of welded steel wire mesh

| Open area(pitch) | 30mm | 50mm | 75mm | 100mm | 150mm | 200mm |

|---|---|---|---|---|---|---|

| Wire diameter (mm)/size | 1m×2m | 1m×2m | 1m×2m | 1m×2m (2m×4m) |

1m×2m (2m×4m) |

1m×2m (2m×4m) |

| 2.6 | - | ○ | ○ | ○ | - | - |

| 3.2 | ○ | ○ | ○ | ○ | ○ | ○ |

| 4 | - | ○ | - | ○ | ○ | ○ |

| 5 | - | ○ | - | ○ | ○ | - |

| 5.5 | - | - | - | - | ○ | - |

| 6 | - | ○ | - | ○ | ○ | ○ |

| 10 | - | - | - | - | ○ | ○ |

Specifications of welded SUS wire mesh

| Open area(pitch) | 30mm | 50mm | 75mm | 100mm | 150mm | 200mm |

|---|---|---|---|---|---|---|

| Wire diameter (mm)/size | 1m×2m | 1m×2m | 1m×2m | 1m×2m | 1m×2m | 1m×2m |

| 2.6 | - | ○ | - | ○ | - | - |

| 3.2 | ○ | ○ | ○ | ○ | ○ | - |

| 4 | - | ○ | - | ○ | ○ | - |

| 5 | - | ○ | - | ○ | ○ | - |

| 6 | - | ○ | - | ○ | ○ | - |